Understanding Fire Sprinkler K-factor

What is a Fire Sprinkler K-factor?

At its core, the K-factor is a measure of the size of the bore in a fire sprinkler. It determines how much water a sprinkler will discharge when activated. As a K-factor number grows larger, so does the size of the opening in the sprinkler and accordingly the amount of water that can flow through that sprinkler. Importantly, the K-factor of a sprinkler is innately linked with the pressure and flow moving through that sprinkler via the following formula.

Q = Water flow in gallons per minute (gpm)

K = K-factor (gpm/psi1/2)

P = Pressure in pounds per square inch (psi)

Photo Credit: Viking Group Inc.

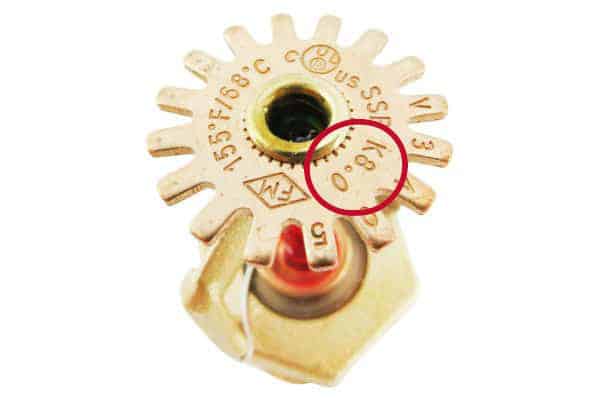

Residential fire sprinklers typically have K-factors ranging from 3.0 to 5.8, with common increments being 3.0, 3.7, and 4.9. The K-factor of a sprinkler can be found etched on the sprinkler itself. Adhering to design plans and installing the correct K-factor sprinklers in designated locations is crucial for compliance and functionality.

Why K-factors Matter

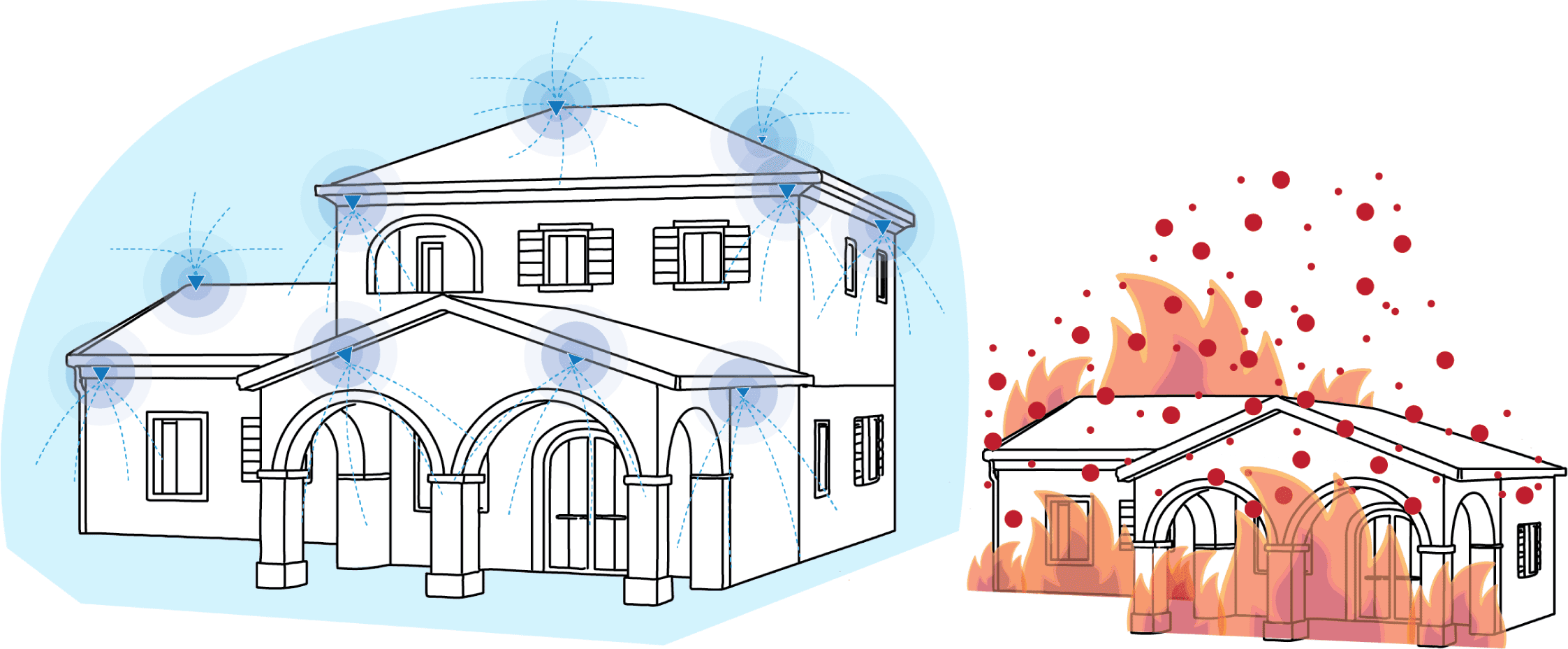

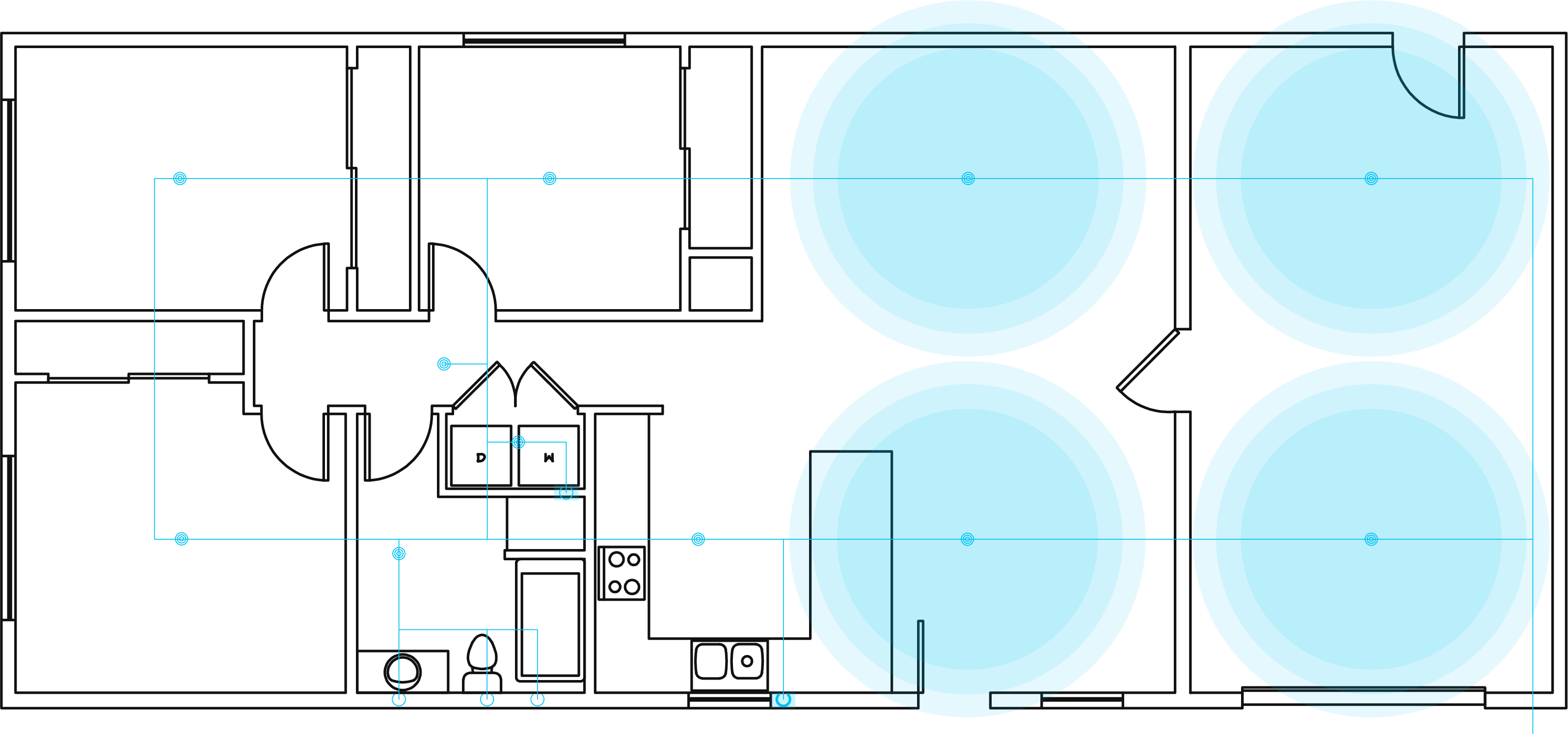

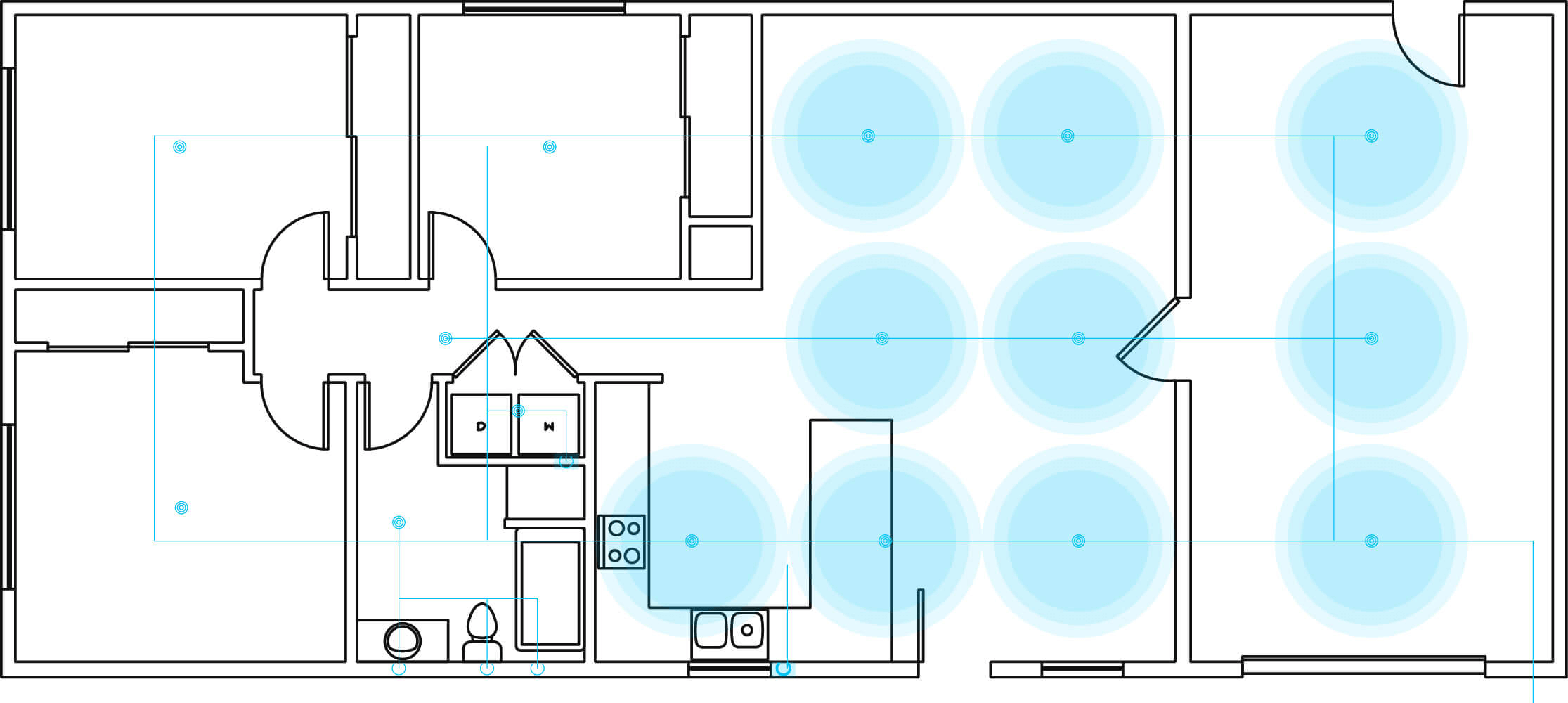

The K-factor of a sprinkler influences its water flow and spray coverage

Higher K-factors allow sprinklers to cover larger areas but require a greater water supply.

Lower K-factors demand less water but necessitate more sprinklers to provide adequate coverage.

For single-family residences governed by NFPA 13D, the fire sprinkler system must be designed to support the simultaneous operation of two sprinklers. This requirement aligns with studies showing that 85% of house fires are controlled by a single sprinkler, while 99% are contained by 2-5 flowing sprinklers. (NFPA Research 2024).

K-factors and System Design

K-factors play a critical role in fire sprinkler system performance, impacting flow rates, pressure requirements, and coverage areas. By selecting the right K-factor, designers can optimize fire protection efficiency while meeting NFPA standards.

Common Flow Requirements

K-factor 4.9 sprinklers: Require approximately 13 gpm at 7 psi (per the formula provided above), equating to 26 gpm for 2 sprinklers.

K-factor 3.0 sprinklers: Require approximately 8 gpm at 7 psi, equating to 16 gpm for 2 sprinklers.

Coverage and Spacing

It is important to note that sprinklers can be used for various spacing configurations, but the typical spacing below reflects what is achievable with the minimum allowable pressure at the sprinkler (7 psi, as dictated by NFPA 13 (§28.2.4.11.1)).

K-factor 4.9 sprinklers: Require approximately 13 gpm at 7 psi (per the formula provided above), equating to 26 gpm for 2 sprinklers.

K-factor 3.0: 12’ x 12’ spacing

K-factor 3.7: 14’ x 14’ spacing

K-factor 4.9: 16’ x 16’ spacing

If you are wondering why the K-Factors are used for these typical spacings, the answer lies in the fact that residential sprinklers are required to achieve a specific water flow density over the area they are protecting. These spacings ensure sprinklers achieve the required water flow density of 0.05 gpm/ft² (§10.1.1, NFPA 13D).

10.1.1* Sprinklers That Are Listed with Specific Discharge Criteria.

Require approximately 13 gpm at 7 psi (per the formula provided above), equating to 26 gpm for 2 sprinklers.

This means that every square foot of floor that is being protected by a residential sprinkler must receive 0.05 gallons of water each minute if the sprinkler were to activate.

Example Calculation

- Protection Area: 12’ x 12’ (144 ft²)

- Our K-factor formula, revisited: Q = K√P

- K = 3.0; P = 7 psi

- Text BoxWater flow at the minimum allowed pressure of 7 psi

Q = 3.0 √7

Q ≅ 8 gpm

Notice that a K-factor 3.0 sprinkler discharging 8 gpm cannot protect a 14’ x 14’ area because it would only be capable of delivering a density of 0.041 gpm/ft².

A K3.0 sprinkler can be used to protect a 14’ x 14’ space, but the flow from at the sprinkler (and therefore the pressure at the sprinkler) would need to be increased. The necessary pressure and flow values to achieve specific spacings can be found within technical datasheets of any particular sprinkler.

Photo Credit: Quick Response Fire Supply

Photo Credit: Brandon Leon from Flickr

Uniform Distribution of Water

Residential fire sprinklers undergo UL testing to confirm they deliver the necessary water flow densities across all points of the area they are protecting. You may notice sprinklers with the same K-factor, but made by different manufacturers, require different flow rates to achieve the same protection spacing. This is due to variations in water distribution performance. For instance:

- Senju SS8464 K4.9: Requires 21 gpm for a 20’ x 20’ area (0.0525 gpm/ft²).

- Viking VK494 K4.9: Requires 20 gpm for the same area (0.05 gpm/ft²).

The difference arises from the Viking sprinkler’s higher observed discharge uniformity during testing.

Special Considerations for Sidewall Sprinklers

Sidewall sprinklers often require higher flow and pressure than pendent sprinklers to achieve the same density. This is due to their lower uniformity in water distribution. Designers must account for these differences to ensure effective coverage.

Strategic Use of K-factors

Selecting the right K-factor balances installation costs and system performance:

- Higher K-factors: Reduce the number of sprinklers but require a greater water supply.

- Lower K-factors: Work with limited water supplies but require more sprinklers. Where possible, using a single K-factor throughout a residence simplifies installation and minimizes errors. However, strategic use of different K-factors in specific locations can optimize performance, provided careful planning and documentation are in place.